Width: 1250mm~3000mm

Length: 4000~12000mm

Thickness: 3mm~150mm

Customize Size: can accept

Surface: Black or Painting

MOQ: 1ton

Price: USD+560~1120+Ton

Payment: 30% TT Deposit+70% Balance before delivery or receive copy BL

Supply Capacity: 5000Ton/Month

Delivery date: 7-35days

Shape: Plate/Coil

MOQ: Regular size have no MOQ,Customize size 50MT

Sample: Free sample

Delivery Details : Steel strip binding, fumigating pad wood fork points, and unloading Standard Export Seaworthy Package.Suit for all kinds of transport,or as required

20ft GP:5898mm(Length)x2352mm(Width)x2393mm(High)

40ft GP:12032mm(Length)x2352mm(Width)x2393mm(High)

40ft HC:12032mm(Length)x2352mm(Width)x2698mm(High)

20feet container load 25tons coils whose length is under 5.8m

40feet container load 25tons coils whose length is under 11.8m

Description

Hot Rolled High Strength carbon steel plate steel sheet A517 A514 S690Q S890Q STRENX 700 900 960

The main properties of high strength steel plate are high strength, especially in the normalizing or normalizing and tempering state, which has higher comprehensive mechanical properties.

Typical Steel Grade

| Steel/Grade | Standard | Size Range | Delivery Condition |

| Q420B/C/D/E | GB/T1591 | ≤150 | TMCP/N |

| S460M/ML | EN10025-4 | ≤100 | TMCP |

| S460Q/QL/QL1 | EN10025-6 | ≤150 | Q+T |

| S460N/NL | EN10025-3 | ≤200 | N |

| Q500C/D/E | G8/T 1591 | 150 | TMCP/Q+T |

| Q550C/D/E | GB/T 1591 | ≤150 | TMCP/Q*T |

| Q690C/D/E | GB/T16270 | ≤220 | Q+T |

| S690Q/QL/QL1 | EN 10025-6 | ≤220 | Q+T |

| QB90C/D/E | GB/T16270 | ≤150 | Q+T |

| Q890Q/QL/QL1 | EN 10025-6 | ≤150 | Q+T |

| Q960C/D/E | GB/T 16270 | ≤100 | Q+T |

| S960Q/QL | EN 10025-6 | ≤100 | Q+T |

| A514GrB/E/F/H/Q | ASTM A514 | ≤200 | Q+T |

Mechanical property

| Impact Test | ||||||||

| Grade | Size | Rel(Mpa) | Rm(Mpa) | A(%) | Temp(℃) | KV2(J) | ||

| S460QL | 100 | 453 | 572 | 29 | -60 | 108 | 120 | 153 |

| Q550D | 25 | 655 | 725 | 20 | -20 | 260 | 227 | 233 |

| Q690D | 50 | 765 | 815 | 18 | -20 | 183 | 158 | 169 |

| S690QL1 | 150 | 767 | 842 | 20 | -60 | 103 | 83 | 78 |

| A514Gr.Q | 127 | 712 | 822 | 27 | -46 | 90 | 76 | 96 |

| Q890E | 100 | 938 | 986 | 16.5 | -40 | 101 | 108 | 137 |

| Q960E | 11 | 1030 | 1053 | 15 | -40 | 89 | 126 | 142 |

Welding Properties

Manual Metal Arc Welding of Q690D(20mm):

Welding at preheating temperature 100℃ by using heat input of 16KJ/CM;

Impact energy of welding metal: >100J;

Maximum impact energy through Heat Affected Zone: =70J

Tensile strength of welding joint:920MPa, close to base material.

Bending test of welding joint: no cracks shown after root bending and face bending.

Hardness of a quarter welding joint and hardness of root: <350 (HV0.5), corresponding to the microstructure of HAZ at the joint;

Hardness of upper and lower surface in HAZ: ≤400(HV0.5)

Microstructure of welding joint:

1.Weld: mainly bainite;

2.Overheated Zone: mainly bainite, also showing martensite and a small amount of ferrite.

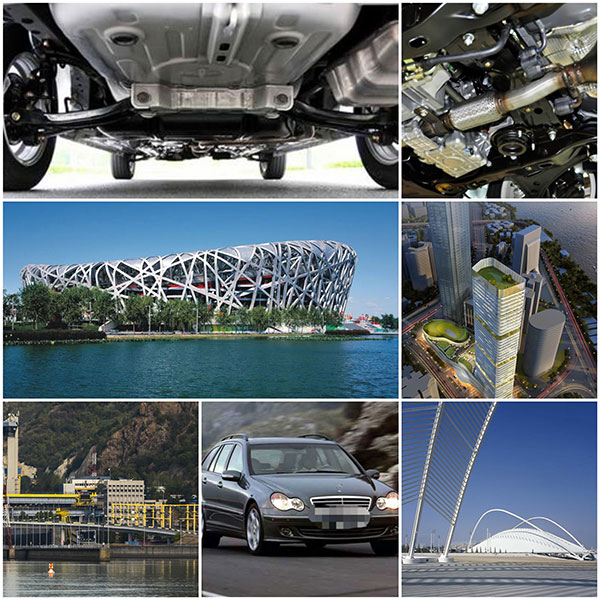

Application

Mainly used in large ships, Bridges, power plant equipment, medium and high pressure boilers, high pressure vessels, rolling stock, lifting machinery, mining machinery and other large welded structural parts.