Performance: high hardness, Wear-resistant , high-temperature resistant

Material: steel

Color: Original color/can also be custom painted

Initial hardness: 200-250HB

Hardness value after hardening:>300HB

Sample:free

MOQ: 1tons

Price: 1200-1500usd/ton

Payment: 30%TT Advance + 70% Balance

Supply Capacity: 5000 tons/per month

Delivery date: 7-10days

Advantage:delivery fast

Service: Provide Customize Service

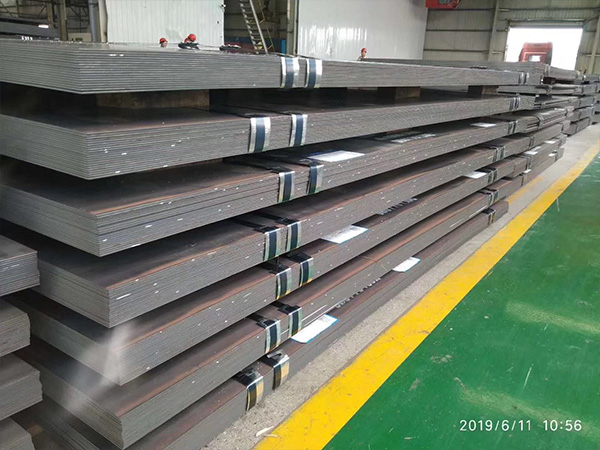

packaging: Steel strapping

1).20ft GP:5898mm(Length)x2352mm(Width)x2393mm(High),Loading 28 Tons

2).40ft GP:12032mm(Length)x2352mm(Width)x2393mm(High),Loading 28 Tons

3).40ft HC:12032mm(Lengh)x2352mm(Width)x2698mm(High),Loading 28 Tons

Description

Mn13 is the best choice among wear-resistant materials such as strong impact and high-pressure material wear. It has work hardening characteristics that otherwear-resistant materials cannot match. Under the action of large impact load or large contact stress, the surface of the steel plate will be processed. After hardening, the surface hardness is rapidly increased from HB200 to above HB500, resulting in a highly wear-resistant surface layer, while the inner austenite of the steel plate still maintains good impact toughness. There are two biggest characteristics of high manganese steel: one is that the greater the external impact load, the higher the wear resistance of its own surface layer; the other is that as the surface hardened layer gradually wears, new work hardened layers will continue to form. The special performance of high manganese steel is suitable for making wear-resistant components that can withstand high impact materials for a long time.

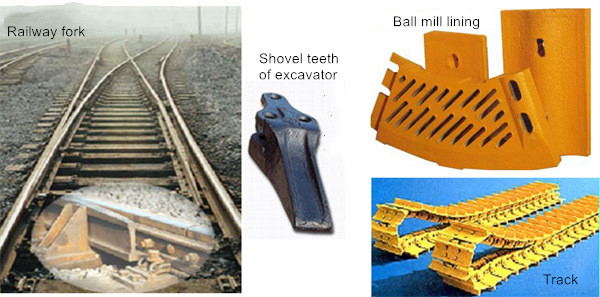

Application

Mn13 High Manganese Steel Plate has been widely used in metallurgy, mining, building materials, railways, electric power, coal and other mechanical equipment for a long time. Especially in recent decades, with the rapid development of modern industry and the rapid advancement of science and technology, high manganese steel has become the preferred wear-resistant material in advanced equipment such as maglev trains, safes, bulletproof vehicles, rock drilling robots, new tanks, etc. . Many new materials and modern surface engineering technologies are still unable to compare with high manganese steel in terms of cost performance